- Home

- Products

- Fertilizer Machinery

- Rotary Dryer

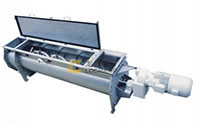

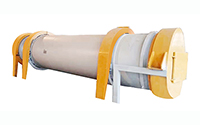

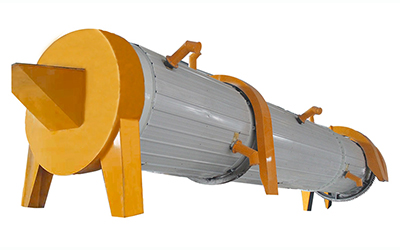

Rotary Dryer

Description

Inside the cylinder of LoChamp’s rotary dryer is set with a secondary granulation area depending on the properties of the materials, which can implement secondary granulation while the materials are dried, so that the final surface smoothness of the materials is higher. In addition, a new multi combination lifter device is employed on the rotary dryer, which overcomes the "wind tunnel" phenomenon of traditional dryers, with a high thermal efficiency and a about 20% reduction of coal consumption.

Application

The rotary dryer is mainly used for secondary granulation and drying after granulation of organic fertilizers, which can also be applied to the drying of granular and powdery materials in chemical, metallurgical, building materials, mining and many other industries.

| Specification | Power (kw) | Volume (m3) | Production capacity (t/h) |

| Φ1.5*14 | 15 | 24.7 | 3-5 |

| Φ1.8*18 | 22 | 45.8 | 5-8 |

| Φ2.0*20 | 37 | 62.8 | 8-10 |

| Φ2.4*22 | 45 | 99 | 12-15 |

- The cylinder is combination structure made by auto submerged arc welding to enhance its strength and welding aesthetic extent.

- Composite plates are used in the cylinder to increase the contact area between the materials and the heat energy, so that the heat energy exchange is sufficient, the energy consumption is low, and the efficiency is high.

- The matched fuel-fired furnace is also designed as high efficiency energy saving type, which can minimize production cost for customers.

Lochamp Import & Export Co.,Ltd.

Tel.: +86-0371-89910659

Fax: +86-0371-89910657