LoChamp fertilizer line is usually used to process different fermented organics into organic fertilizers. The equipment configured in this production line are the best combination for processing fertilizers. All parts in contact with the organics are made of quality stainless steel, capable of working at best even under the most aggressive fertilizers. Our machines can turn the following raw materials into premium fertilizers:

- Stalk, bean pulp, cottonseed meal and other agricultural wastes.

- Chicken manure, cattle, sheep and horse manure, rabbit dung and other animal manures.

- Distillers’ grains, vinegar residue, cassava residue, sugar residue and other industrial wastes.

- Household wastes and municipal sludge.

- Proportioning

- mixing

- pelleting

- drying

- cooling

- screening

- coating

- bagging

-

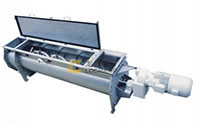

- Mixing Machinery Functional features: mixer separates the free-flowing powders, continuously and softly mixing the materials.

-

- Rotor Drum Granulator Functional features: fertilizers are humidified and then fully tumbled in the rotary drum granulator, finally forming agglomerates.

-

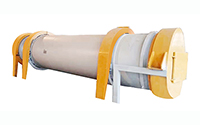

- Rotary Dryer Functional features: the rotary dryer is equipped with a secondary granulation area. This makes the materials granulated twice while being dried, finally creating homogeneous mixture.

-

- Rotary Drum Cooler Functional features: this rotary drum cooler quickly cools the 65-85℃ pelleted organic fertilizes to close to room temperature. This allows the products be packaged timely and prevents the products from agglomeration during storage and transportation.

-

- Cylinder Grading Screen Functional features: the grading screen is used to sieve the dry fines or pellet materials.

-

- Fertilizer Coating Machine Functional features: rotary coating drum can effectively prevent the fines from agglomeration. And bio-enzyme can also be added.

-

- Automatic Bagging Scale Functional features: Bagging scale adopts computer automatic metering and seam packing.

Customer case

As a manufacturer of large fertilizer processing equipment focused on client demands, LoChamp is your most reliable partner by virtue of good product quality and perfect after-sales service. We offer complete organic fertilizer and compound fertilizer equipment, and will continue to serve you sincerely as always. Be free to contact us if you have any problems related to the fertilizer production. And our bridle-wise staffs are at your service at any moment!