- Home

- Products

- Animal Feed Equipment

- Cooling Machine

- Circular Cooler

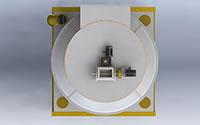

Circular Cooler

Description

The SKLNW series circular cooler is designed by our company with a series of improvements on the basis of traditional coolers. The area of the air inlet and outlet are increased to 10 times that of traditional coolers to reduce cooling air resistance, which can save up to 20% energy consumption of the cooler. Its chamber is a full circular design achieving real no-material-residue design, which can avoid cross-contamination of materials. This circular cooler is suitable for the cooling of particle materials shorter than 40mm in length.

Application

This circular cooling equipment is widely applied to cooling treatment section in the feed processing industry, which is suitable for the cooling treatment of various particle feeds, such as pelleted feeds, expanded feeds, extruded feeds, sheet feeds etc.

| Model | Temperature after cooling | Power(kw) | Yield(t/h) | Outline dimensions(mm) |

| SKLNW20 | ≤RT+3℃ | 0.75 | 8-15 | 2444×4776×2312 |

| SKLNW25 | ≤RT+3℃ | 0.75 | 15-20 | 2874×4848×2732 |

Advantages of the circular cooler

The pneumatic discharge mechanism features lower total power consumption of instant start because it does not need to start the motor frequently compared with traditional electric discharge mechanism, thus it can save 80% electric energy.

An access door is provided on the front of the equipment to facilitate the equipment daily maintenance and running condition observation.

Lochamp Import & Export Co.,Ltd.

Tel.: +86-0371-89910659

Fax: +86-0371-89910657